On this flood defence site, the previously installed steel access plates which were used to securely stow away flood defence doors had deformed which, together with their weight...

Read MoreCategory: Press Release

Heavy trench covers are history

Once in a while, a product will come along whose performance will drive a change in standards across entire industries. Like stainless steel. Or concrete. Or a trench cover which is over 80% lighter than the cast iron traditionally used, eliminating the need for costly specialised lifting equipment and the accompanying health and safety hazards. And, unlike metal and concrete infill covers, it’s engineered from a GRP composite material which is inert and impervious to corrosion from water and salt, as well as many other corrosive constituents.

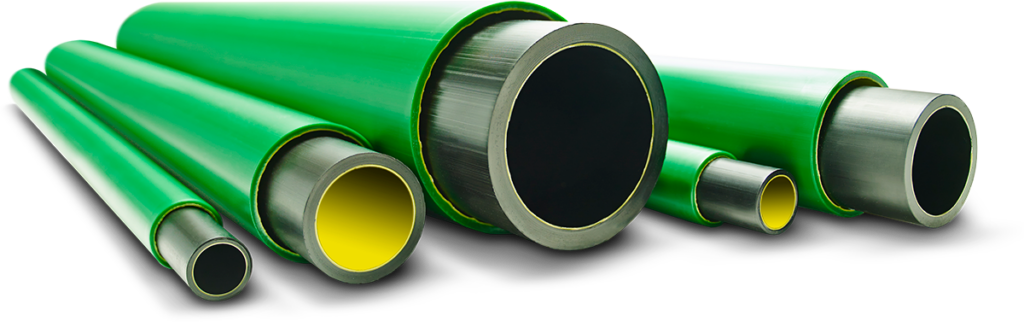

Data centres specify KPS high density polyethylene (HDPE) piping and Fibrelite composite access covers to safeguard 24/7 365 operation

In an increasingly connected digital world, data centres are critical. With 3.6 million m2 in use by data centres in Europe alone and over 70 projects (851,000 m2) in progress in 12 European countries (ResearchAndMarkets1), their growth continues to accelerate to meet the needs of cloud technology.

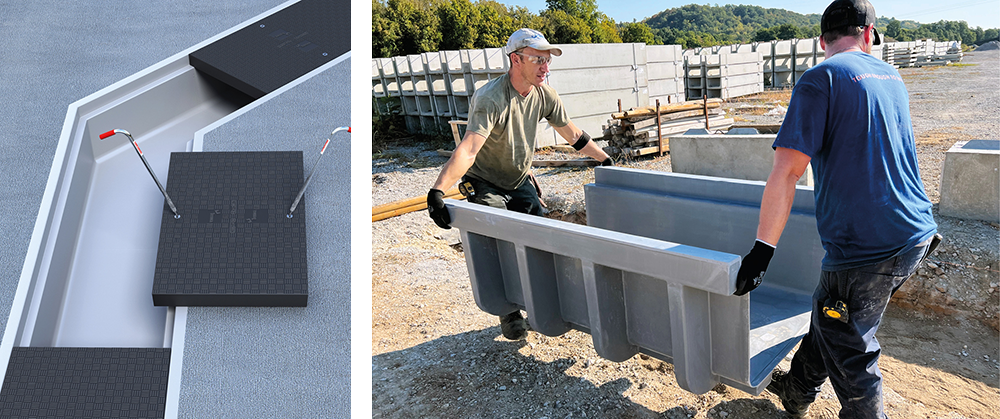

Strategic partners: Precast and preformed troughs and Fibrelite’s ‘made to measure’ GRP trough covers

Composite access cover manufacturer Fibrelite has formed strategic partnerships with a number of major manufacturers of precast and preformed troughs (also known as trenches, channels and ducts) in Europe and the USA (including Fibex and Trenwa) to create new collaborative product offerings integrating Fibrelite covers and precast and preformed troughs.

Access all areas: How lightweight composite covers are making drainage and sewerage access safer

As nuclear decommissioning authorities seek to increase project efficiency while maintaining the highest possible standards of safety, companies responsible for the clean-up of sites look to new products and processes.

One of the UK’s largest nuclear decommissioning projects specifies Fibrelite composite access covers to improve safety and efficiency

As nuclear decommissioning authorities seek to increase project efficiency while maintaining the highest possible standards of safety, companies responsible for the clean-up of sites look to new products and processes.

Magnox leads the way in manual handling in the nuclear decommissioning industry by specifying Fibrelite

Fibrelite were approached by Magnox to provide numerous replacement manhole and trench covers to replace the existing degrading concrete and cast-iron covers. This works had to be co-ordinated and delivered within a tight schedule to provide a safe, efficient and consistent solution within the decommissioning work being undertaken at Hinkley Point A.

Composite manhole and trench access cover manufacturer Fibrelite releases new case study book featuring over 120 installations in over 90 countries

Fibrelite is excited to announce the release of their second edition case study book, a library of over 120 technical installations showcasing Fibrelite’s manhole and trench access covers as well as underground containment systems and sister brands KPS (piping) and OPW (fuelling products).

Announcing Fibrelite’s new generation of radio frequency friendly manhole covers – designed for remote underground monitoring

Following increasing demand for Radio Frequency (RF) friendly manhole covers, composites manufacturer Fibrelite has developed a new range of manhole access covers, designed to support data transfer between antennas underground and aboveground.

The cloud… covered!

The construction challenges of cloud and data centers continue to change and evolve with the ever-increasing use of and reliance on the facilities. Today sees an increasing focus on efficiency, reliability and reduced downtime, while build schedules continue to tighten.

Load bearing access covers are going lightweight

Conventional load-bearing access and manhole covers are heavy, liable to corrosion and difficult to install and remove. The question facing modern architects and developers is how to retain the accessibility and strength, but improve upon the practicality, durability and performance.