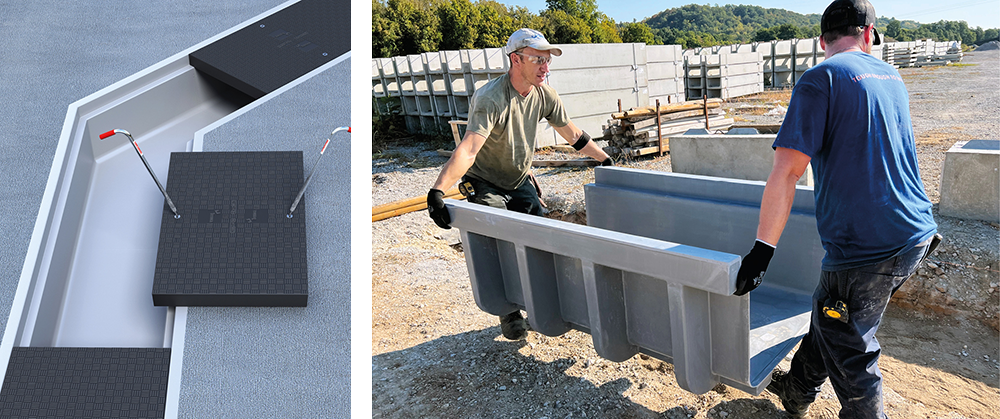

On this flood defence site, the previously installed steel access plates which were used to securely stow away flood defence doors had deformed which, together with their weight...

Read More- Home

- Products

-

- Sectors

-

Select a sector/industry:

Ports &

AirportsGas Petrol Stations

& ForecourtsPower

GenerationPrecast Concrete Trench Systems

Data

Centers CentresStadiums

& LeisureMilitary

& Defense Defence

Health &

Social Care

Radio

Frequency

Manufacturing

Facilities & Food ProcessingRail, Trams

& Underground

Roadside &

Access Roads

Water & Water

TreatmentPublic

AreasSteam

CoversShopping Centers Centres

& Retail Parks

-

- Global Projects

-

Technical case study library

Stadiums

& Leisure

Military

& Defense Defence

Health

& Social Care

Radio

Frequency

Manufacturing Facilities & Food Processing

Shopping Centers Centres

& Retail ParksTelecoms

Our latest case study:

-

- Technical Hub

-

- News

-

-

-

Latest news:

Solving underground power challenges in EV charging: Fibrelite in MobilityPlaza

The below extract from Mobility Plaza’s latest article discusses how Fibrelite meets the demands of the fast-growing EV sector with modular, accessible underground trench access systems.

Read MoreBreaking new ground and new markets: OPW in erpecnews

erpecnews Editor Nick Needs recently interviewed our Sales Director, OPW Retail Fuelling EMEA, Denis Pokrovsky, to discuss our growth into new markets. “The Middle East and Africa have slightly different…

New case study: UK power station specifies custom Fibrelite trench covers

Approximately 625 metres of custom designed and manufactured Fibrelite GRP trench covers and frames were specified for this project at one of the UK’s largest power stations…

Poznan Municipal Transport Company require an easy access covering solution

With a fleet of 200 buses stationed, serviced, and refuelled at MPK Poznan depot in Poland, the Poznan Municipal Transport Company required an easy access covering solution…

events:

-

-

-

- About Us

- Contact Us