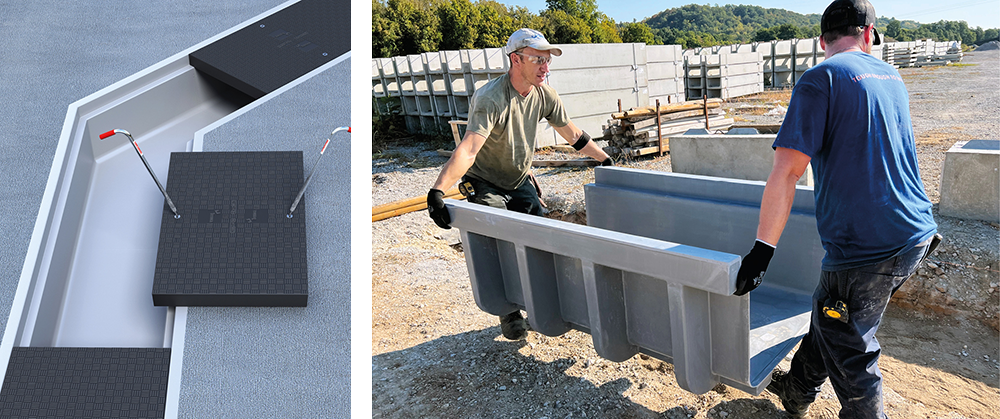

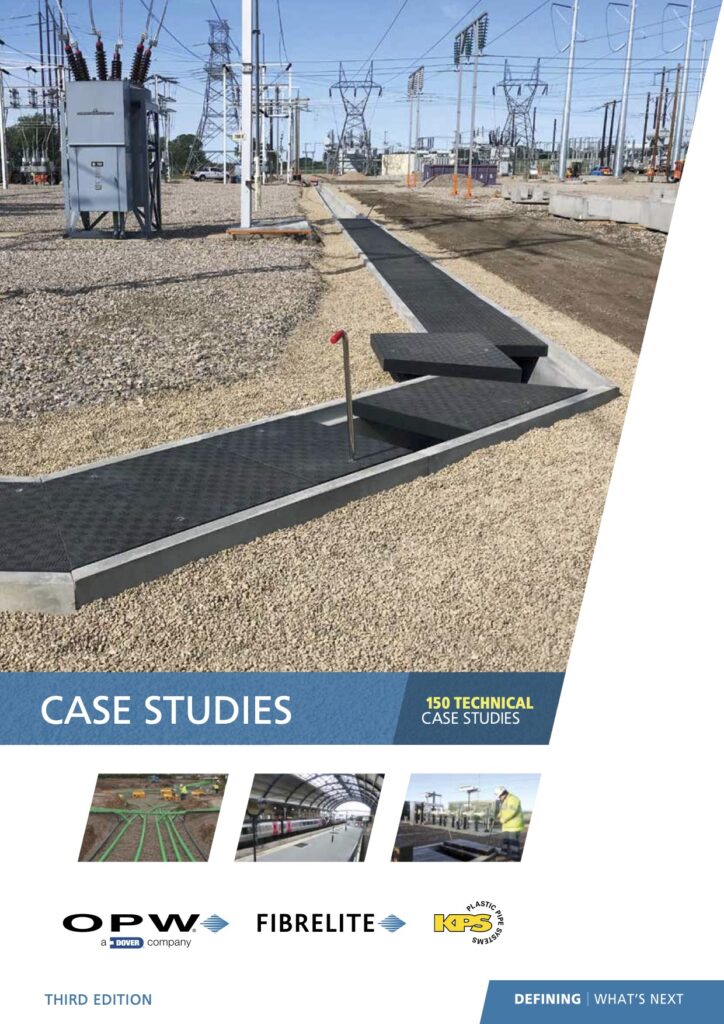

This EV bus depot required a swift replacement for their heavy concrete trench covers over their HV cable trench to remedy manual handling issues. Fibrelite supplied a custom engineered and...

Read MoreManufacturing and Research Facility, North West, UK

Fibrelite were contacted to source a GRP covering arrangement for service duct trenches at a major UK based manufacturing and research facility. Operational difficulties posed by the previously existing concrete cover slabs…

Support Facility, Bahrain

The previously installed steel covers had permanently deformed under heavy operational loads and sat in an uneven recess, resulting in the covers being unstable.

Engine Manufacturing Facility, Bristol, UK

BBI (Beacons Business Interiors Ltd) required a lightweight retrofit trench covering arrangement to replace the installed failing concrete covers.

Airport Maintenance Facility, UK

Fibrelite were contacted to provide a bespoke GRP composite trench covering arrangement to fit precast concrete service trenches at a UK airport maintenance facility.

Royal Canadian Mint, Winnipeg, Canada

In the search for a safer simpler alternative to previously installed heavy steel panels, the Royal Canadian Mint approached Fibrelite.

Culvert Access Solution, UK

A UK construction company required a covering solution for a newly constructed culvert. Due to the shape it required a “cassette” of bespoke covers and additional support beams.

Biopharmaceutical Plant, UK – Phase 2

Having supplied a retrofit solution to a service trench for HGV’s the customer approached Fibrelite to design a bespoke trench cover.

Aerospace Facility, UK

Fibrelite supply bespoke trench covers over concrete trenches that house essential pipework and service supplies. Our covers are designed for these types of complicated applications.

Educational Facility Grease Pits, UK

The previous covers claimed to be odour tight but weren’t, resulting in the constant emission of a terrible odour. The heavy galvanised covers were also extremely difficult to remove.

Glass Processing Plant, Miętno, Poland

Fibrelite and Polish distributor, Corrimex, provided B125 load rated Fibrelite composite covers to a glass glazing and glass processing plant in Miętno…