On this flood defence site, the previously installed steel access plates which were used to securely stow away flood defence doors had deformed which, together with their weight...

Read MoreTrinity Shopping Centre, Leeds, UK

The consulting engineers specified Fibrelite for this project for ease of access to cable ducts that run all over the site. The panels are non-slip for a safe working environment in a busy centre.

Leeds Market, UK

A series of 8 trenches were previously covered by traditional concrete panels but with constant heavy foot traffic the covers had crumbled and created trip hazards.

Indiana University, Bloomington

Indiana University approached Fibrelite looking for steam rated manhole covers for new vaults and in replacement of existing covers on the Bloomington campus.

Water Facility, Devon, UK

Fibrelite were invited to conduct a site survey, as the client desired a simple replacement for their previously installed heavy cast iron recess (access) covers with concrete infill.

Rail Maintenance Facility, Doncaster, UK

This Doncaster rail maintenance facility required custom-made trench covers to accommodate a selection of different sized piping.

Hospital, Yorkshire, UK

The previously installed concrete trench access covers over an oxygen pipework trench at this hospital were causing a number of issues due to both their weight and deterioration.

Leading Middle East Oil Company

OPW is proud to show how their products provided a leading Middle East oil company with a long-term solution for their Qatar expansion programme through their in-country distributor.

Manufacturing and Research Facility, North West, UK

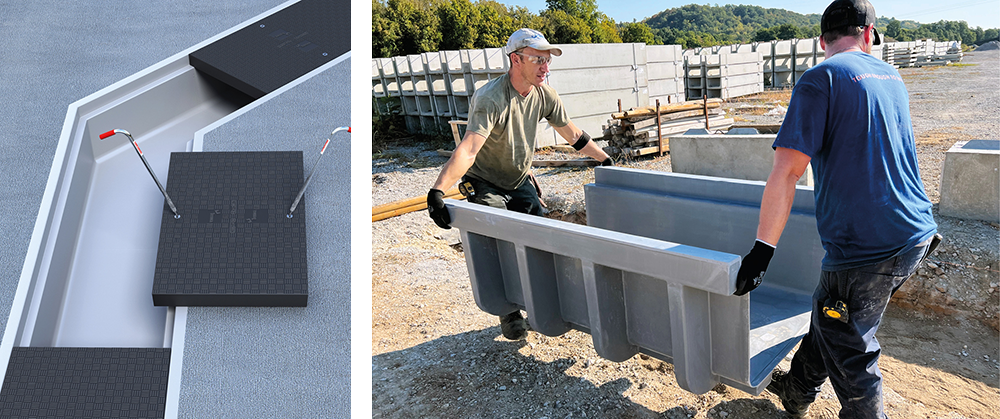

Fibrelite were contacted to source a GRP covering arrangement for service duct trenches at a major UK based manufacturing and research facility. Operational difficulties posed by the previously existing concrete cover slabs…

Nottingham City Hospital, UK

Hilton Bodill Construction contacted Fibrelite on behalf of Nottingham City Hospital, who required a lightweight and strong modular covering system for their newly re-routed service trench, which replaced the traditional heavy concrete slabs. These protect and provide access to the…

Vancouver City Hall, Canada

Vancouver City Hall required a safe replacement for previously installed concrete trench access covers located on a walkway outside of the hall, over a generator.