Fibrelite’s custom GRP composite trench covers were specified from the outset of this multi-million-pound refurbishment of a historic 1930s Art Deco cinema in the North of England.

Read MorePower Generation

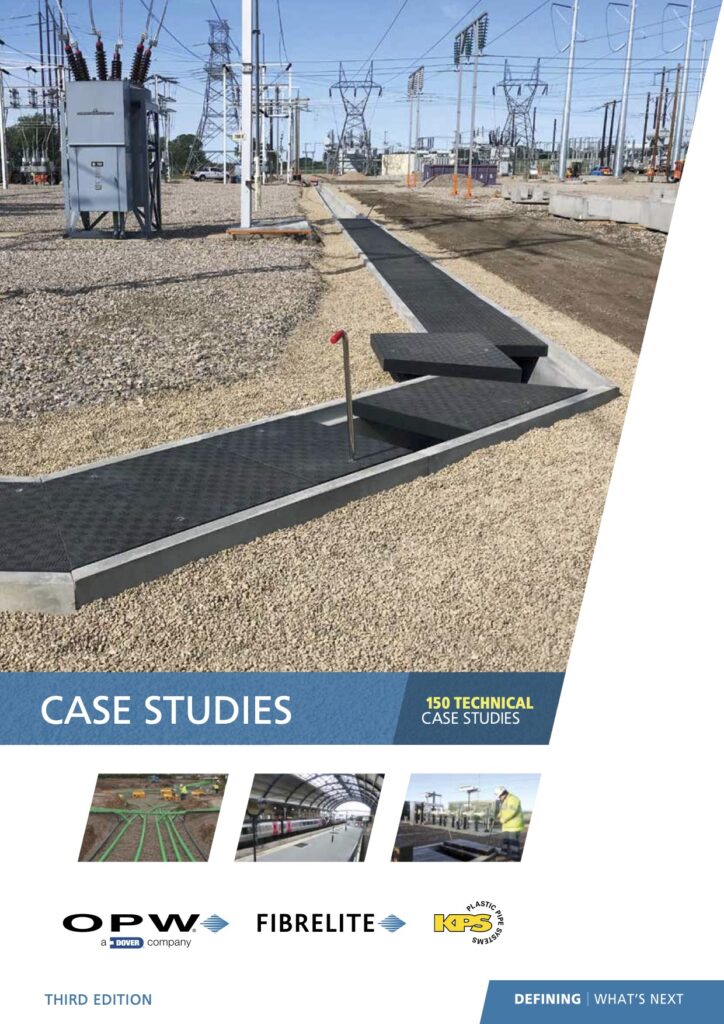

Magnox, The National Grid, and many more leading companies are specifying Fibrelite trench covers to improve efficiency and eliminate health and safety manual handling risks

Upgrading aging metal and concrete infrastructure

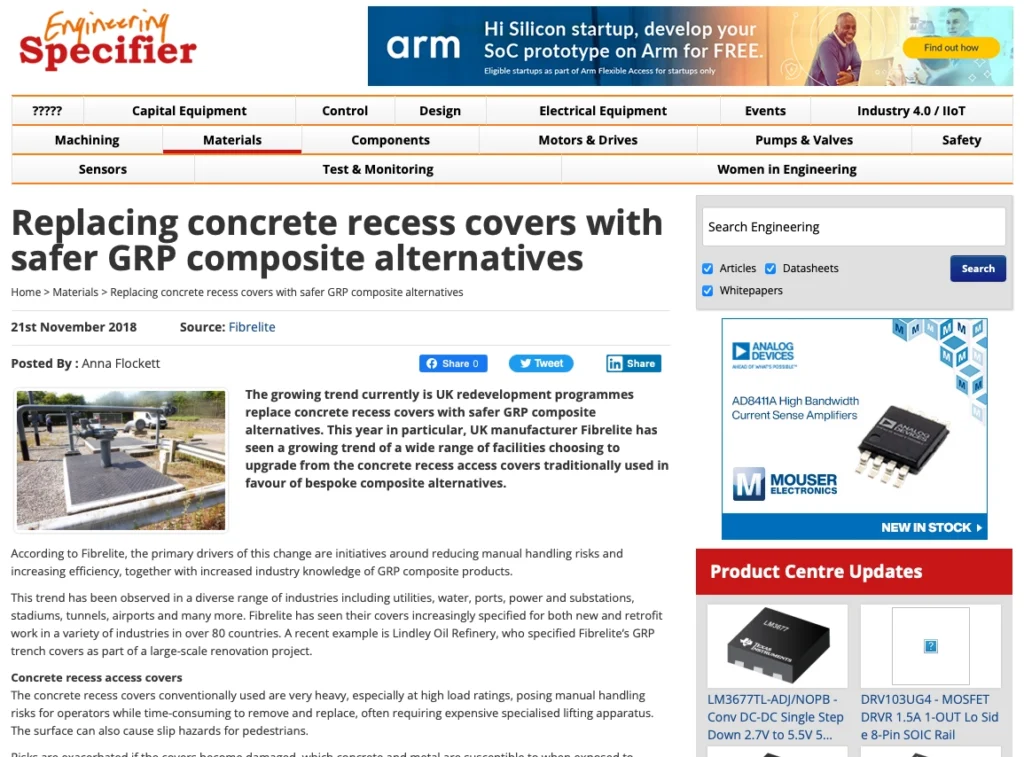

Back in the 1960s when many of these facilities were built, heavy concrete and steel or cast-iron trench covers were the only option available. Today, many sites are discovering deterioration of the structural integrity of their steel and concrete trench covers, exacerbating manual handling risks, and, where located on road crossings, potentially restricting vehicular access to certain areas of the site.

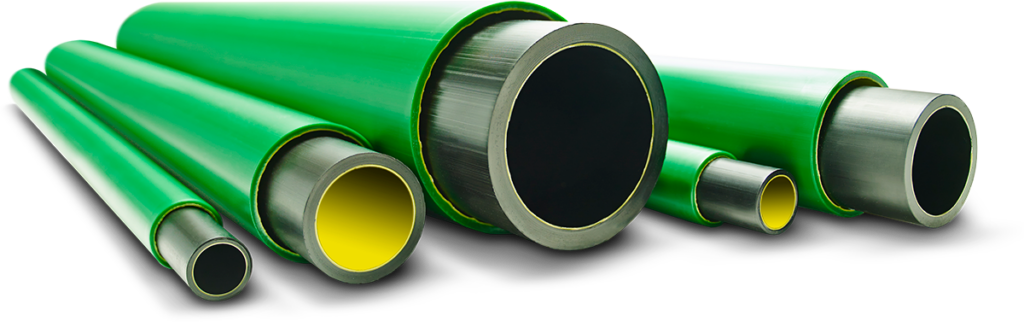

Lightweight, safe, retrofit FRP GRP composite trench and manhole covers

Many sites and companies (traditional electrical turbine and gas power stations and substations, nuclear, renewables and decommissioning) like Magnox and The National Grid are choosing to upgrade to Fibrelite’s made-to-measure heavy-duty lightweight FRP GRP composite trench covers, especially on road crossings, where both a high load rating and frequent safe access are required.

With an unrivaled unrivalled strength-to-weight ratio, Fibrelite’s highly engineered FRP GRP composite trench and manhole covers are significantly lighter than metal and concrete, yet just as strong, and can be retrofitted directly into the existing frames/rebate, avoiding the need to break concrete. Unlike metal and concrete infill covers, they are inert and impervious to corrosion from water and salt, as well as many other corrosive compounds.

Installed by...

- Wind farms

- Solar power plants

- Gas-fired turbine power plants

- Nuclear power plants

- Coal-fired power plants

- Electrical substations

- Gas substations

- Nuclear decommissioning

Products specific to power generation

Trench

Covers

VIEW PRODUCTS +

Square / Rectangular

Manhole Covers

VIEW PRODUCTS +

Precast Concrete

Trench Lids

VIEW PRODUCTS +

Underground

Enclosures

VIEW PRODUCTS +

Accessories

VIEW PRODUCTS +

Trench

Covers

VIEW PRODUCTS +

Square / Rectangular

Manhole Covers

VIEW PRODUCTS +

Precast Concrete

Trench Lids

VIEW PRODUCTS +

Underground

Enclosures

VIEW PRODUCTS +

Accessories

VIEW PRODUCTS +

Cadent Gas, Lancashire, UK

Cadent Gas continues to replace their previously installed heavy cast iron with concrete infill trench covers with Fibrelite’s lightweight retrofit GRP composite...

Read MoreUK Power Station

Approximately 625 metres of custom designed and manufactured Fibrelite GRP trench covers and frames were specified for this project at one of...

Read MoreCadent Gas, Warrington, UK

Fibrelite was approached by Cadent Gas to provide a long-lasting trench cover solution, which would alleviate some onsite issues associated with previously...

Read MoreHinkley Point (A) Nuclear Power Station, Somerset, UK

Fibrelite were approached to provide numerous replacement manhole and trench covers to replace the existing degrading covers.

Read More