Fibrelite’s custom GRP composite trench covers were specified from the outset of this multi-million-pound refurbishment of a historic 1930s Art Deco cinema in the North of England.

Read MoreAbout us

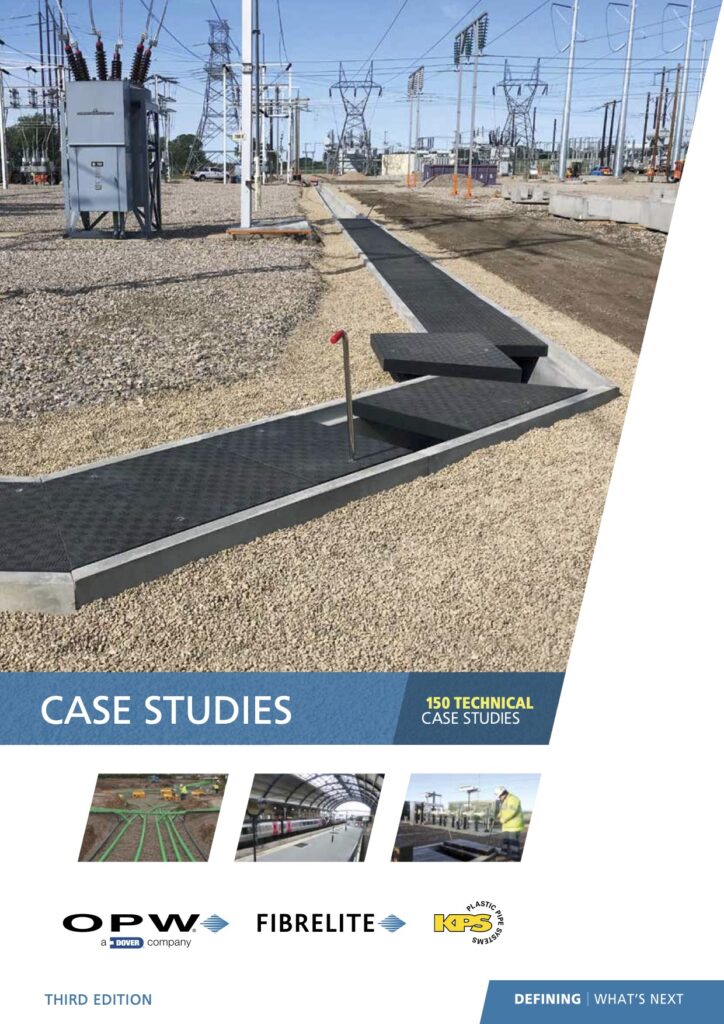

Fibrelite is a global leader in the manufacture and development of highly engineered FRPGRP composite manhole covers, trench covers, steam covers and underground containment systems.

Who we are...

Founded on core values of quality and innovation since 1980, Fibrelite is proud to be at the forefront of composite technology, with creations including the world’s first composite manhole cover! Recent developments include the first composite F900 load rated trench cover and first composite multiport system.

Since 2013, Fibrelite has been a part of OPW (a Dover company) allowing us to offer an unprecedented portfolio of complementary best-in-class products.

Fibrelite products are manufactured in the US, UK and Malaysia and supported by a global network of distributors.

Protecting people and the environment while enhancing your business performance.

OPW is a global leader in fully integrated fluid handling, management, monitoring and control solutions for the safe and efficient handling of critical petroleum-derived fluids from the refinery to the commercial and retail points of consumption, including loading systems, rail and transport tank truck equipment, tank gaging gauging equipment and automated fuel management systems, valves and fittings, underground and above ground storage tank equipment, spill containers, overfill prevention devices, secondary containment sumps and flexible piping, fuel dispensing products, including swivels, breakaways, industrial and automatic dispensing nozzles for vapor recovery, gasoline, diesel, and alternative fuels, and clean energy fueling fuelling nozzles and accessories for LPG, hydrogen and CNG.

OPW also manufactures automated vehicle wash systems. OPW has 1,650+ employees with manufacturing operations in North America, Europe, Brazil, China and India and sales offices around the world. OPW is an operating company within the Fluids segment of Dover Corporation (NYSE: DOV).

Additional information is available at www.opwglobal.comContact us to discuss your project

Dover is a diversified global manufacturer and solutions provider with annual revenue of over $8 billion. We deliver innovative equipment and components, consumable supplies, aftermarket parts, software and digital solutions, and support services through five operating segments: Engineered Products, Clean Energy & Fueling, Fuelling, Imaging & Identification, Pumps & Process Solutions and Climate & Sustainability Technologies. Dover combines global scale with operational agility to lead the markets we serve. Recognized Recognised for our entrepreneurial approach for over 70 years, our team of approximately 24,000 employees takes an ownership mindset, collaborating with customers to redefine what’s possible. Headquartered in Downers Grove, Illinois, Dover trades on the New York Stock Exchange under “DOV.”

Additional information is available at dovercorporation.comDover is a diversified global manufacturer and solutions provider with annual revenue of approximately $8 billion. We deliver innovative equipment and components, consumable supplies, aftermarket parts, software and digital solutions, and support services through five operating segments: Engineered Products, Clean Energy & Fueling Fuelling, Imaging & Identification, Pumps & Process Solutions and Climate & Sustainability Technologies. Dover combines global scale with operational agility to lead the markets we serve. Recognized Recognised for our entrepreneurial approach for over 65 years, our team of over 25,000 employees takes an ownership mindset, collaborating with customers to redefine what’s possible. Headquartered in Downers Grove, Illinois, Dover trades on the New York Stock Exchange under “DOV.”

Additional information is available at www.dovercorporation.com