On this flood defence site, the previously installed steel access plates which were used to securely stow away flood defence doors had deformed which, together with their weight...

Read MoreLeading Middle East Oil Company

OPW is proud to show how their products provided a leading Middle East oil company with a long-term solution for their Qatar expansion programme through their in-country distributor.

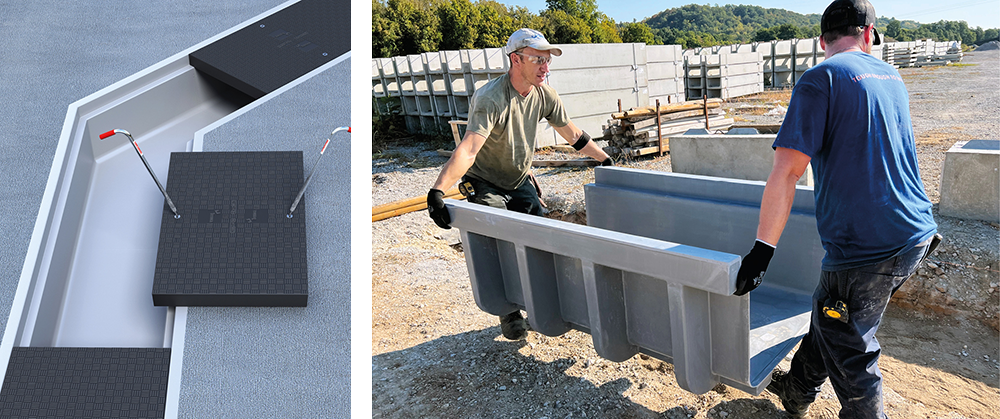

Shell Retail Fuelling, Eastfield, UK

Our UK site team discovered that two of the tanks had double manways that were too close together to install traditional tank sumps and required a bespoke solution work for a successful install.

Major Oil Company, Belgium

A major international oil company with large Benelux presence approached OPW looking for a reliable long-lasting containment system for a new build filling station.

Shell, North Hampshire, UK

OPW’s UK engineering team created a bespoke chemical bonding system to attach GRP Fibrelite tank sumps to the existing upstands, eliminating the need for expensive adaptor plates.

BP, UK

BP required a below ground remote fill with opposing pipe exit positions to ensure consistent fill layouts for tanker deliveries and to reduce installation time and costs.

Petrol Forecourt & Green Area, Thailand

Fibrelite’s lightweight, watertight manhole covers and tank sumps have been specified by a leading oil company in Thailand.

Petro Systems, Ireland

Petro Systems Management (PSM) has upgraded from using steel pipework in their installations to using KPS conductive plastic piping, enabling simple, fast, long lasting installations, especially when used in conjunction with Fibrelite tank sumps and seal kits as pictured here.

Lukoil, Bulgaria

OPW provided Lukoil, a major Russian based oil company, with an easy-install underground containment system including KPS pipework and Fibrelite tank sumps, for a new build filling station in Bulgaria. Ease of access, longevity and the speed of installation were of the highest importance.

Tora Petrol, Istanbul, Turkey

Fibrelite provided Tora Petrol with fully watertight, GRP composite manhole covers which help protect fuel tanks across Turkey’s Marmara region. These proved invaluable during the July 2017 floods, where Fibrelite’s composite manhole covers…

Fuel Retailer, Romania

A Romanian oil company approached OPW to provide an easy to install, reliable above ground fill point solution…