Fibrelite’s custom GRP composite trench covers were specified from the outset of this multi-million-pound refurbishment of a historic 1930s Art Deco cinema in the North of England.

Read MorePrecast Concrete Trench Panels Covers

A powerful partnership...

Lightweight FRP GRP lids custom designed for precast concrete and preformed FRP GRP trenches troughsAll load ratings A15 – F900

All load ratings from Pedestrian

to 90 tons

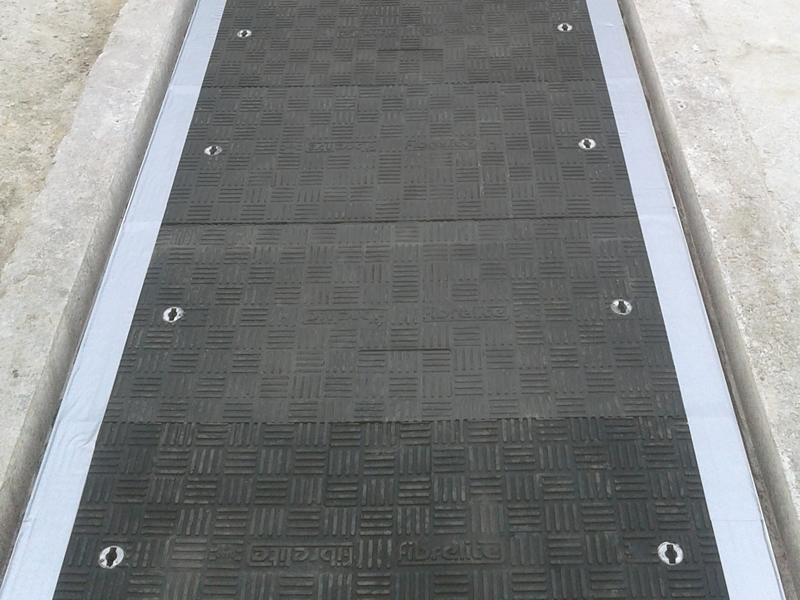

Fibrelite’s extensive range of composite trench covers can withstand the same heavy loads as traditional materials, at a fraction of the weight; while the load-carrying capacity of precast concrete trenches are derived from their structural qualities and don’t rely on the strength/quality of surrounding backfill materials.

Safe manual removal

- Lightweight GRP lids custom designed for precast concrete and preformed GRP troughs

- Options available for all layouts and configurations

- Unparalleled protection and accessibility

- Designed for safe manual removal

- GRP Composite covers are available from A15 to F900

- Proven durability

- Lightweight FRP lids custom designed for precast concrete and preformed FRP trenches

- Options available for all layouts and configurations

- Unparalleled protection and accessibility

- Designed for safe manual removal

- FRP Composite covers are available from Pedestrian to 90 tons

- Proven durability

New precast trench cover technical guide

Dependable protection

Our highly engineered composite covers are inert, very durable and capable of withstanding traffic and harsh field conditions for many years, while precast concrete trenches protect against adverse weather conditions and resist the majority of corrosive substances, providing long-term protection for underground utilities.

Proven durability

Contact us for more information on creating custom solutions and installations

Unrivaled Unrivalled customization customisation

Custom designed and manufactured Fibrelite trench panels covers for biopharmaceutical manufacturer

The custom designed and manufactured panels covers were fitted into the existing frames

Fibrelite aluminum aluminium encapsulating frame installed on top of flat top precast trench trough

Precast flat top trench trough with cover recess and side edge flags formed on site by contractor

Precast trench trough with a factory formed recess to accommodate trench panels covers

“Combining high-performance, lightweight Fibrelite lids with our low-cost precast trench bases delivers a very high-value solution for our customers.

They get unparalleled strength and durability at a lower cost than has ever been seen in the market.”

George Schurr President/COO, Trenwa Inc.

Custom molded moulded stepped covers

Fibrelite trench covers can be custom molded moulded to be stepped, allowing them to be retrofitted into existing frames with shallow rebates while maintaining their structural integrity (independently tested).

This allows direct replacement of previously existing metal covers, or installation in existing precast or preformed concrete trenches. Stepping can also reduce manufacturing cost and weight.

New precast trench cover technical guide

Industries using our systems

- Substations

- Power plants

- Co-gen facilities

- Waste water treatment plants

- Wind farms

- Solar farms

- Correctional institutions

- Universities

- Industrial plants

- Telecommunication sites

- Refineries

- Data centres

Recent precast case studies

Northern Hospital, UK

Fibrelite were contacted by Laing O’Rourke regarding this project at this hospital redevelopment project. Concrete duct trenches troughs had been sourced prior to the trench covers, meaning that (prior to contacting Fibrelite)...

Read MoreEV Bus Charging Depot, London

This EV bus depot required a swift replacement for their heavy concrete trench covers over their HV cable trench to remedy manual handling issues. Fibrelite supplied a custom engineered and manufactured modular trench...

Read MoreGlobal Satellite Services Provider, USA

This large multinational satellite services provider has specified the Fibrelite Trenwa partnership trench and cover system for their latest satellite earth station antenna facility in the U.S. The partnership system combines...

Read MoreAre you a precast concrete manufacturer interested in designing a FRP GRP offering?

Fibrelite precast partnerships

In 2014, Fibrelite and precast concrete trench manufacturer Trenwa formed a strategic partnership to create joint product offerings: Trenwa’s heavy-duty precast concrete road crossing trenches topped with Fibrelite’s traffic rated composite trench covers.

Since 2014 when the partnership began, Trenwa has sold well over a hundred of their precast trench systems with Fibrelite trench covers, now installed in electrical substations, wastewater treatment plants, chemical refineries and many other applications across North America.

As increasing numbers of people learn about the benefits of using Fibrelite trench covers, many are looking to upgrade previously installed concrete or steel trench covers. To meet this demand, Trenwa have worked with Fibrelite to design and manufacture custom molded moulded composite trench covers to fit Trenwa’s existing line of precast multi-duty trench systems.